Redefining Hospital Performance Through Energy-as-a-Service

Optimum Energy helps healthcare systems modernize critical infrastructure without upfront capital. Our Energy as a Service model delivers reliable, efficient, and sustainable operations that reduce costs and improve performance. With innovative technology that ensures ongoing results, hospitals gain resilient energy systems, lower lifecycle costs, and greater financial flexibility to focus on delivering exceptional patient care.

What We Do

In times of crisis, the combination of Optimum Energy’s expert team of support engineers and the ability for your staff to remotely monitor and troubleshoot your HVAC equipment from anywhere helps you prevent minor issues from becoming serious ones. This means hospital executives and facility staff can rest assured that your mission critical HVAC equipment continues to operate, allowing everyone to focus on serving patients and saving lives.

How Hospitals Benefit

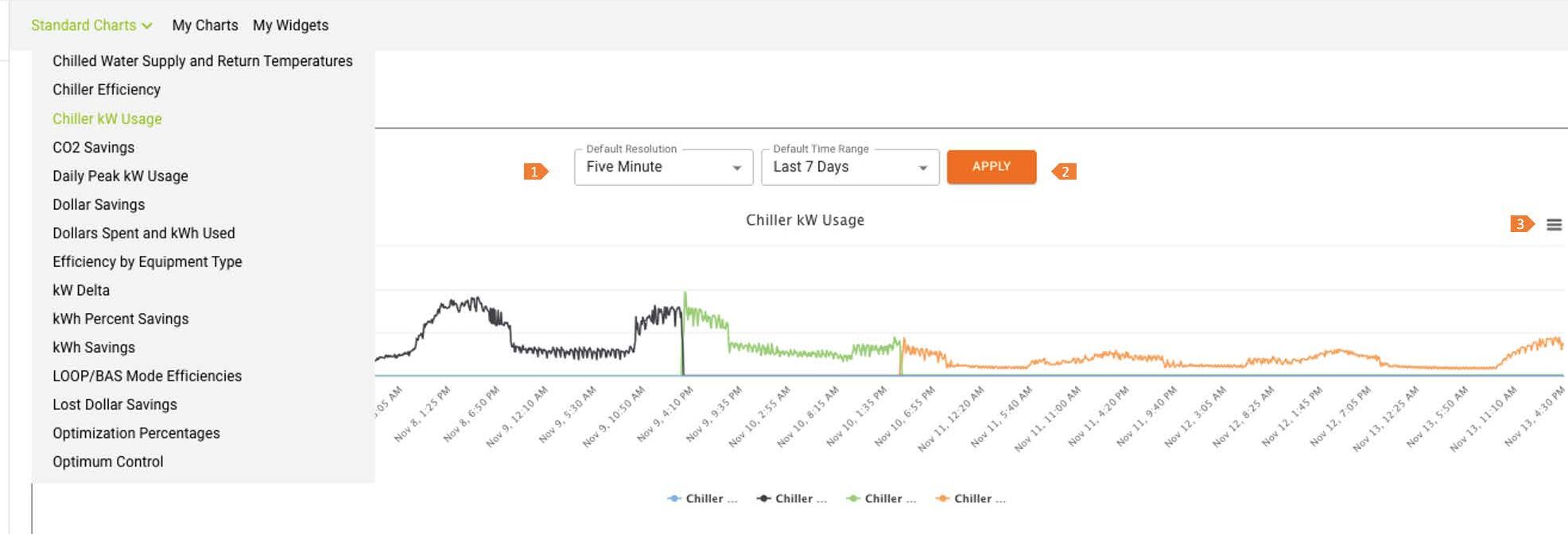

The OptiCx® platform dynamically and automatically adapts to fluctuating conditions to yield the lowest possible kW/ton, ensuring building systems achieve peak performance day after day, year after year. The patented Real-Time Dynamic Commissioning™ technology fights performance drift by detecting and addressing issues in real time. Sophisticated software algorithms and modeling techniques also produce a detailed, real-world baseline, which, combined with the OptiCx® Measurement and Verification tool, gives you performance data and energy savings results in real time. This allows you to quickly retool and reset when necessary.

Optimum Energy’s solutions typically reduce energy expenditures by up to 40%, helping you achieve HVAC optimization and giving you an average payback between one and five years. OptimumLOOP® also dramatically reduces water use, further contributing to sustainability goals. Additionally, Optimum Energy helps reduce HVAC equipment maintenance costs and wear and tear by balancing energy use among all components.

OptiCx® advances sustainability goals and reduces greenhouse gas emissions by up to 50% from baseline. Reduce emissions at the source as a result of running more efficiently, aligning your organization with the carbon laws and compliance set to arrive by 2030. It also contributes to Energy Star ratings (up to 18 points) and LEED certification for both existing buildings (up to 24 Energy and Atmosphere credits) and new construction (up to 19 EA credits).

Optimum’s scalable, modular approach to energy optimization standardizes and deploys HVAC management best practices across an enterprise portfolio, regardless of building type, equipment, or BAS vendor. You can address one system at a time, within one building or across many facilities. Our centralized energy management system makes it easy to access the information you need.

Solutions that Support Healthcare

“In 20 years of experience, I’ve never seen chiller optimization like this,” said Morlang. “It has more depth, it analyzes the system as a whole, and it uses advanced algorithms to adjust for the system you have in a holistic way. We’re exceeding our predicted savings, and I expect that to continue year after year.””

“Through this project, we are more aware of energy efficiency and savings. It’s helping the team see the bigger picture—we’re not just providing chilled water, but we’re doing it as efficiently as possible and, ultimately, saving money.”

“The monthly analytics reports are very valuable. They give us insights into potential problems with our machines—starting with overall efficiencies and then diving deeper into the details with things like approach temperature degradation on the chillers. We are also looking at how all that information trends over time—combined with Optimum’s experience from other sites, we get a different set of eyes and experience to help drill down into what the machines are telling us.”