Employee Spotlight: Kay John, Lead Operations Program Manager

Employee Spotlight: Kay John, Lead Operations Program Manager

At Optimum Energy, our talented team is the driving force behind everything we achieve. With our Employee Spotlight Program, we shine a light on the passionate, innovative individuals who deliver exceptional results for our clients every day. Discover the inspiring stories and unique talents of the people who make Optimum Energy a leader in our industry!

This month, we’re sitting down with Kay John, Lead Operations Program Manager at Optimum Energy. Kay joined Optimum at the beginning of 2024, and brings over a decade of program and project management experience to the optimization team. Since then, Kay has been instrumental in ensuring projects are delivered on schedule, driving efficiency and fostering a culture that emphasizes accountability and reliability.

Kay is also the chair of Optimum’s internal ESG program, managing not just programs that reduce carbon footprints and accelerate one’s path to net-zero, but also ensuring Optimum Energy remains an active example of the sustainable practices we promote. Colleagues recognize Kay’s commitment to leaving the world a better place while helping others do the same, as well as for embodying values like curiosity, collaboration and enthusiasm.

Can you share your journey with Optimum Energy and how your role has evolved since you joined?

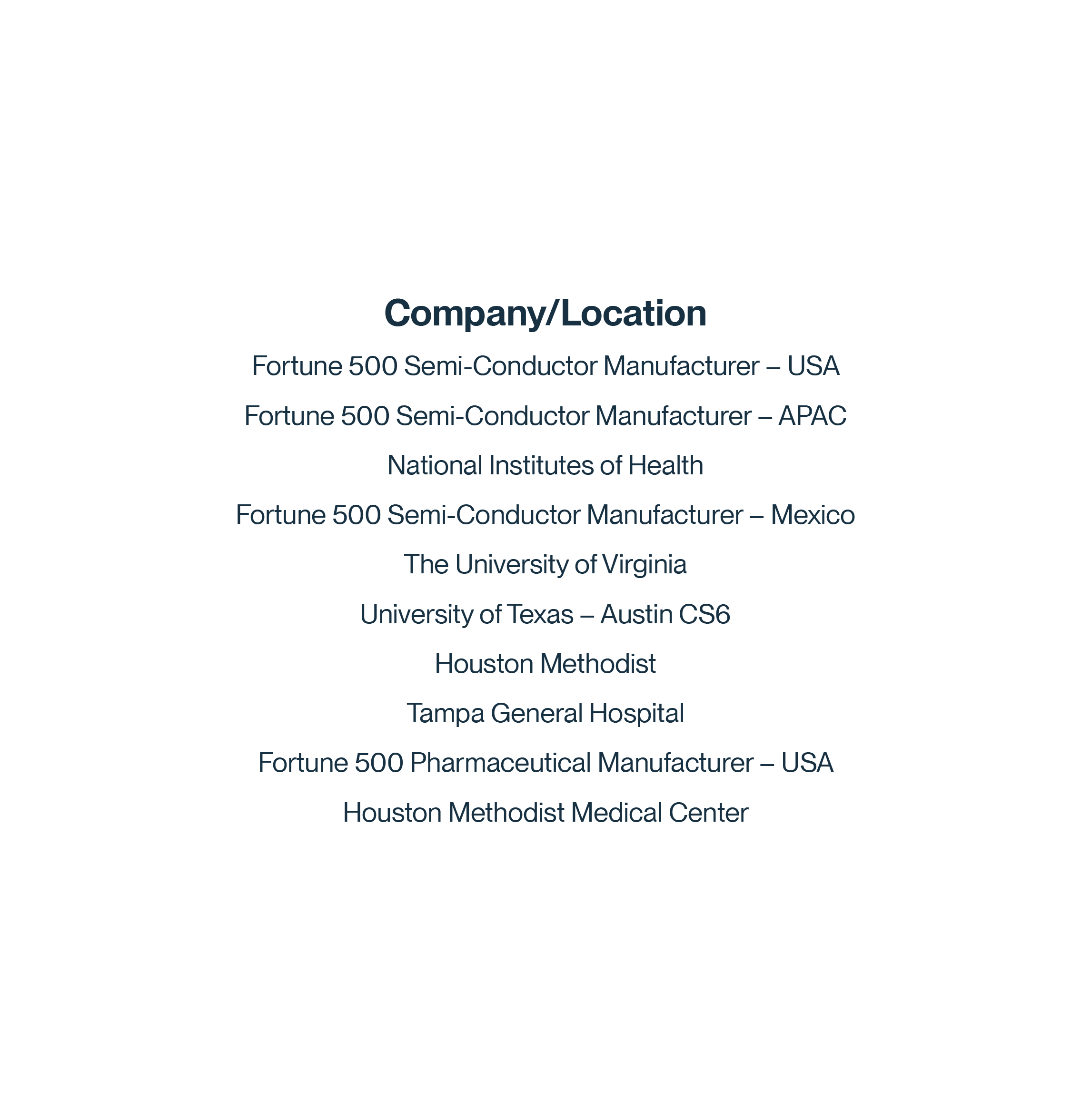

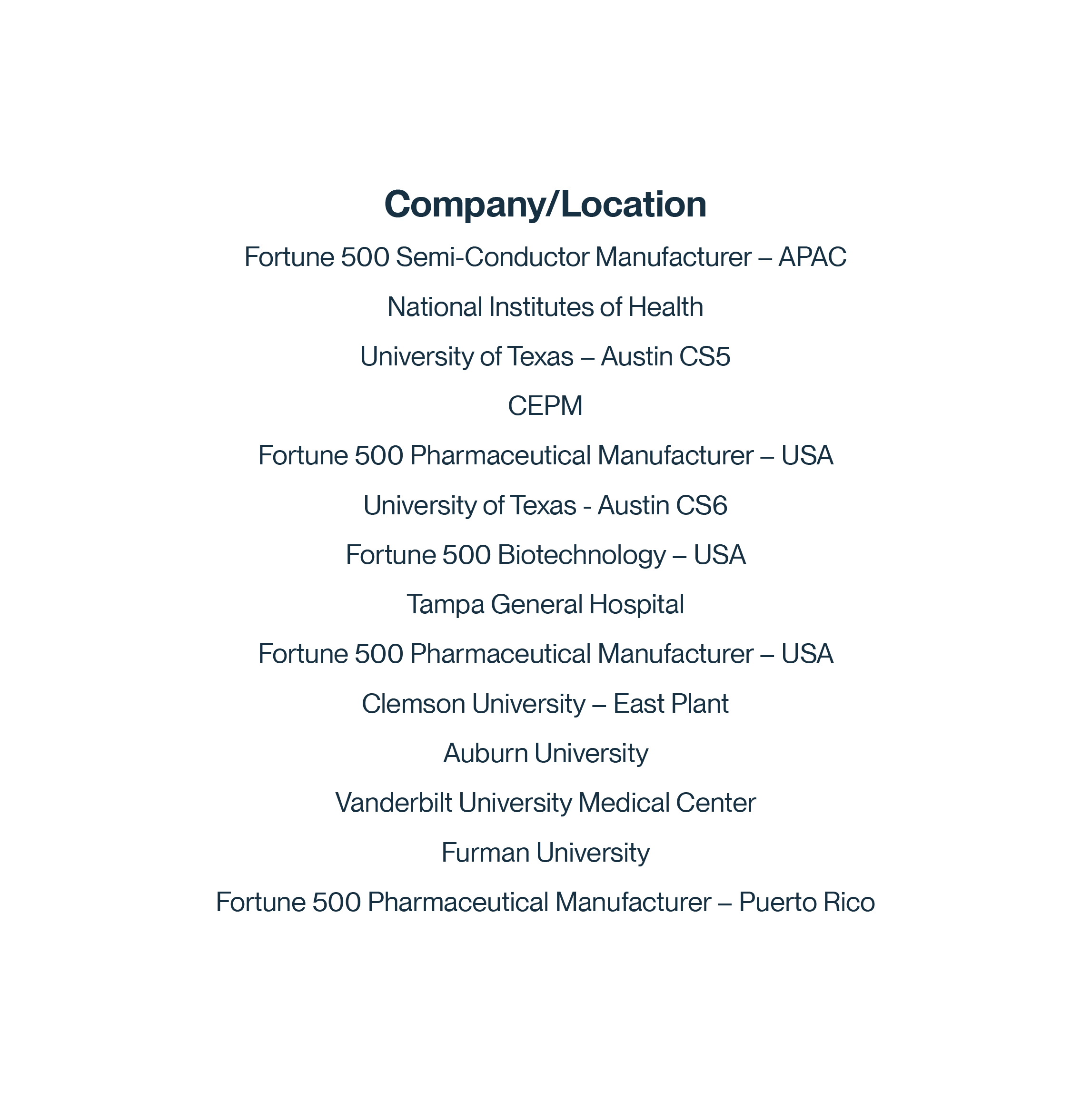

“I joined Optimum Energy in January 2024 as a Senior Project Manager. After working in supply chain and software for almost a decade, I was excited to dive into a new industry that more closely aligned my work with my passion for environmental sustainability. As a Project Manager, I worked closely with our Engineering and IT teams to deploy OE’s optimization software to higher education campuses, hospitals, and manufacturing facilities all over the world. After nine months in this role, I was promoted to lead the PMO team as a Lead Operations Program Manager. My team manages the OE customer project portfolio and internal company programs.”

What is your favorite part about working at Optimum Energy?

“The people I work with are brilliant. I am fortunate to work with Engineers who are experts in the HVAC and Energy space, and I have gained so much knowledge working alongside them to deliver significant energy savings to our customers.”

Describe an accomplishment at Optimum Energy of which you are particularly proud.

“Last year, we created the first ESG (Environmental, Social, Governance) program within Optimum Energy to develop reporting and monitoring of OE’s greenhouse gas emissions. In managing this program, I get to collaborate with teammates across all departments in our organization to identify and develop new sustainability-driven company policies. I’m proud of the work we are doing to report and manage the size of our carbon footprint, as CO2 emissions from energy (scope 2) reduction is a key service we provide to our customers.”

What is one thing you have learned while working here that has significantly impacted your approach to energy optimization?

“According to the International Energy Agency, “The operations of buildings account for 30% of global final energy consumption and 26% of global energy-related emissions (8% being direct emissions in buildings and 18% indirect emissions from the production of electricity and heat used in buildings).”

Every year, we save hundreds of millions of pounds of CO2 from entering the atmosphere, which in turn saves our customers millions of dollars on their utility bills. It’s a beautiful alignment of cost and consciousness that centers on the requirement of controlled temperatures inside of critical buildings like hospitals, campuses, and manufacturing facilities.”

Whether you’re looking to join a team that’s redefining energy optimization—or want one of our experts to lead your next project—Optimum Energy is ready to deliver. Connect with us to explore career opportunities or discover how we can help you achieve lasting performance and sustainability results.